Sectorial research laboratory “Mechanization and Automatisation of Handing and Construction Works”

The laboratory was established in 1964 on the initiative of the creative team of the department “Construction, track and handling machines”, headed by a prominent scientist – Ph.D., Professor Victor Stogov – to solve a number of problems related to loading, unloading and warehousing of a wide range of goods transported by rail. In addition, the scientists of the laboratory were tasked to increase the efficiency of work on the construction and maintenance of the railway.

The main directions of scientific activity of the laboratory:

- search of perspective technological schemes of performance of loading and unloading, warehouse and track works;

- development and implementation in the production of technical means of mechanization of loading and unloading, warehousing and track works;

- development of measures aimed at preventing the accumulation and freezing of bulk cargo on the bodies of vehicles and working bodies of machines and mechanisms;

- search for new solutions aimed at restoring the flow of goods;

- development and introduction into production of technical means for maintenance of weight economy;

- development and introduction into production of technical means for performance of shunting works within the industrial enterprises.

For several decades, the laboratory has developed and implemented attachments and mobile devices for various purposes. Some of them, for example, a hinged bulldozer-grab grab, a CSTI HIIT hitch, a conveyor car unloading machine, were once awarded gold, silver and bronze medals of the ENEA.

1 – upgraded bucket grip; 2 – autostrop CNDI HIIT; 3 – conveyor device for unloading bulk cargo.

Laboratory developments that have been implemented over the last 5 years include an overhead vibrating unloading machine, a device for leveling bulk cargo in gondola cars and a trolley for calibration of car scales.

The overhead vibrating machine is intended for cleaning of gondola cars from the remains of bulk cargoes and is executed in the form of the hinged replaceable equipment to the gantry, bridge crane or the truck. The advantages of this machine in comparison with the most common overhead vibrators are: higher quality of cleaning (the gondola with wet sand is unloaded in 4 minutes); lower drive power (12 kW vs. 22 kW); increased reliability of the device due to the use of specialized vibration sources; lower noise level due to the use of directed vibration sources; four times less load on the elements of the gondola.

The overhead vibrating machine is intended for cleaning of gondola cars from the remains of bulk cargoes and is executed in the form of the hinged replaceable equipment to the gantry, bridge crane or the truck. The advantages of this machine in comparison with the most common overhead vibrators are: higher quality of cleaning (the gondola with wet sand is unloaded in 4 minutes); lower drive power (12 kW vs. 22 kW); increased reliability of the device due to the use of specialized vibration sources; lower noise level due to the use of directed vibration sources; four times less load on the elements of the gondola.

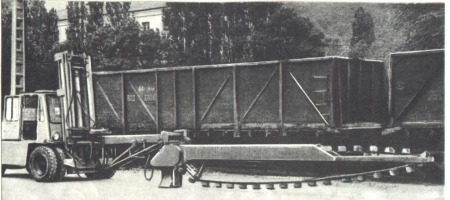

The device for mechanization of the process of leveling bulk cargo from gondola cars, at relatively low power consumption and own weight is able to level the bulk cargo inside the gondola car in a short time. The use of this device allows to increase the productivity of the download process by 3.5 times and to ensure the safety of personnel.

The cart for calibration of car scales is a self-propelled equipment of car calibration cars and is designed to move weights when calibrating car scales used in various sectors of the economy, in particular, by rail.

The cart for calibration of car scales is a self-propelled equipment of car calibration cars and is designed to move weights when calibrating car scales used in various sectors of the economy, in particular, by rail.

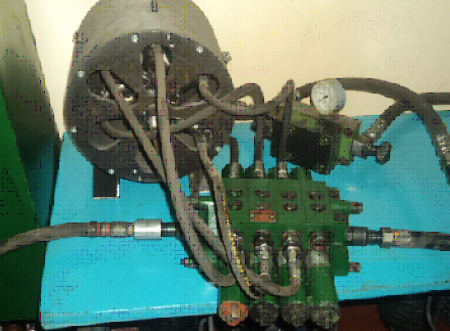

Since 2011 at the department the direction of energy saving in hydraulic systems of BKVRM and  creation of drives of the working equipment on the basis of hydraulic motors of new type has developed, fig. 10, which in 2013 were awarded a diploma of the All-Ukrainian competition “Best Product of the Year”. Also, under the guidance of Professor Remarchuk MP the department developed a stand for diagnosing the hydraulic drive elements of machines and created a laboratory sample of a mill of hydrodynamic action for grinding bulk materials.

creation of drives of the working equipment on the basis of hydraulic motors of new type has developed, fig. 10, which in 2013 were awarded a diploma of the All-Ukrainian competition “Best Product of the Year”. Also, under the guidance of Professor Remarchuk MP the department developed a stand for diagnosing the hydraulic drive elements of machines and created a laboratory sample of a mill of hydrodynamic action for grinding bulk materials.