Sectoral research laboratory “Chemotological”

The sectorial research laboratory “Chemotological” was established by the order of the Minister of Transport and Communications of Ukraine dated 23.05.1995 № 94-Ц on the basis of the Department of “Construction, track and loading and unloading machines” of Kharkiv State Academy of Railway Transport (now Ukrainian State University of Railway Transport).

- physico-chemical and tribological analysis of petroleum products:

- physico-chemical analysis of chemical materials (paints, varnishes, solvents, etc.);

- research and development in the field of fuel and lubricants quality.

The laboratory was established as one of the structures for scientific, technical and practical support for the development of railway rolling stock in terms of testing of petroleum products and other chemical materials for the railway industry.

Today SRL “Chemotological” are certified laboratory , which performs for railways and other industrial physicochemical and tribological analysis of petroleum products, takes part in the field trials of the rolling stock in investigations of the properties of lubricants during working hours.

General view of SRL “Chemotological” (on the left – the department of analysis of tribological properties; on the right – the department of physical and chemical analysis)

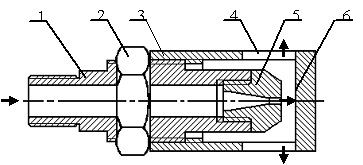

The first developments of SRL “Chemotological” in the field of increasing the wear resistance of machine parts include hydrodynamic  dispersants (HD) of working fluids, oils and diesel fuels, for example, HD with variable gap, developed by Professor Ye. Ventsel and its students, which are built into the lubrication system and are designed to grind mechanical impurities, which reduces the abrasive wear of parts.

dispersants (HD) of working fluids, oils and diesel fuels, for example, HD with variable gap, developed by Professor Ye. Ventsel and its students, which are built into the lubrication system and are designed to grind mechanical impurities, which reduces the abrasive wear of parts.

To conduct research on the impact of HD on the properties of fuels and lubricants (PFL) and wear resistance of parts, SRL “Chemotological” employees have developed specialized measuring and testing stands. Stand for measuring the degree of contamination of oils and diesel fuels by their electrical conductivity. It consists of a measuring cell and a thermometer E6-3.

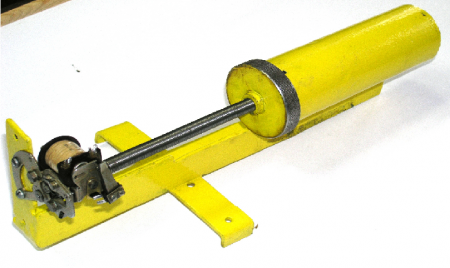

The stand for testing of the fuel equipment of diesel  engines intended for carrying out tests of high-pressure fuel pumps (PNVT) on wear. Studies of the effect of GD on the anti-wear properties of fuel and lubricants confirmed their effectiveness, as evidenced by the results of bench tests of PNVT. Achieved reduction of plunger wear by 1.5 times, depending on the degree of fuel contamination.

engines intended for carrying out tests of high-pressure fuel pumps (PNVT) on wear. Studies of the effect of GD on the anti-wear properties of fuel and lubricants confirmed their effectiveness, as evidenced by the results of bench tests of PNVT. Achieved reduction of plunger wear by 1.5 times, depending on the degree of fuel contamination.

Also, SRL “Chemotological” research is aimed at determining the change in the  concentration of additives in oils and its effect on the rate of wear of the friction units of the elements of hydraulic drives and systems. The laboratory has developed recommendations for the dosed introduction of additives to oils directly in the process of their work, as well as developed a drop dispenser for the introduction of additives.

concentration of additives in oils and its effect on the rate of wear of the friction units of the elements of hydraulic drives and systems. The laboratory has developed recommendations for the dosed introduction of additives to oils directly in the process of their work, as well as developed a drop dispenser for the introduction of additives.

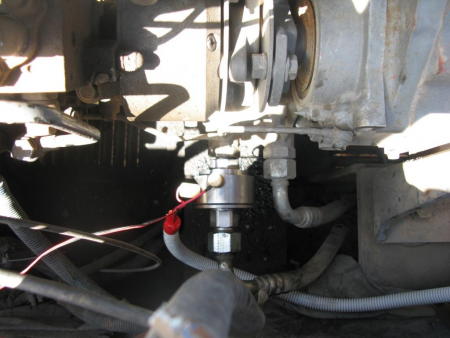

Since 2003 and until now, intensive  research has been conducted to study the effect of external electromagnetic fields on the mechanism of action of additives to lubricants. Such research was initiated by Professor Ye. Lysikov. and his disciples. The influence of the external electrostatic field on the anti-wear properties of

research has been conducted to study the effect of external electromagnetic fields on the mechanism of action of additives to lubricants. Such research was initiated by Professor Ye. Lysikov. and his disciples. The influence of the external electrostatic field on the anti-wear properties of  working fluids (WF) of hydraulic drives of construction and track machines is studied. It is established that the use of electrostatic treatment of WF leads to a reduction in the wear rate of hydraulic drive elements up to 2… 3 times, depending on their operating conditions and fluid contamination. Thus, one of the first was developed and implemented a device for electrostatic treatment of WF single-bucket hydraulic excavators.

working fluids (WF) of hydraulic drives of construction and track machines is studied. It is established that the use of electrostatic treatment of WF leads to a reduction in the wear rate of hydraulic drive elements up to 2… 3 times, depending on their operating conditions and fluid contamination. Thus, one of the first was developed and implemented a device for electrostatic treatment of WF single-bucket hydraulic excavators.

In addition to studies of the effects of electrostatic fields, the laboratory conducts research aimed at improving the reliability of technological equipment by maintaining the required level of purity of lubricants. In this direction, the specialists of the department have developed and implemented at the industrial enterprises of Ukraine mobile stations for fine purification of petroleum products from mechanical impurities. Such stations operate at the following enterprises: CJSC Donetskstal – Metallurgical Plant, OJSC Poltava Mining and Metallurgical Plant, OJSC Turboatom. The developed stations allow to carry out purification of oil products to the 9th class of purity according to GOST 17216-2001 at productivity of 500 l / h, have full weight to 150 kg, are mobile and can be applied also in the repair and maintenance enterprises of transport industry. In order to increase the efficiency of fuel and lubricants of industrial enterprises, the department performs further research in the field of development of energy-saving technologies for refining petroleum products. The main direction of these studies is to study the effect of external force fields of different nature on dispersed water particles dissolved in oils for different purposes. Such research, according to specialists of the department,

Such stations operate at the following enterprises: CJSC Donetskstal – Metallurgical Plant, OJSC Poltava Mining and Metallurgical Plant, OJSC Turboatom. The developed stations allow to carry out purification of oil products to the 9th class of purity according to GOST 17216-2001 at productivity of 500 l / h, have full weight to 150 kg, are mobile and can be applied also in the repair and maintenance enterprises of transport industry. In order to increase the efficiency of fuel and lubricants of industrial enterprises, the department performs further research in the field of development of energy-saving technologies for refining petroleum products. The main direction of these studies is to study the effect of external force fields of different nature on dispersed water particles dissolved in oils for different purposes. Such research, according to specialists of the department,

Among the latest developments of the laboratory in the field of increasing the wear resistance of parts, stationary systems for lubrication of rails in curved sections of the subway track have been developed. The first such system was developed in 2012 and implemented in the same year in KP “Kharkiv Metro” in the race of Art. University – Art. Pushkin. Tests of the station confirmed its effectiveness. Thus, after 2 years of work, according to the expert assessments of the track and tunnel construction specialists, the lateral wear of the rails on the test curve significantly decreased and the growth of defects – the consequences of frictional fatigue of the contact surfaces – slowed down.