Transport Construction Diagnosis Centre

The Transport Construction Diagnosis Centre (TCDS) was established by Order of the Minister of Transport and Communications of Ukraine dd. March 21, 2006, No. 254, as a research subdivision at the Department of Structural Mechanics and Hydraulics of the Ukrainian State Academy of Railway Transport (now Ukrainian State University of Railway Transport).

The Transport Construction Diagnosis Centre (TCDS) was established by Order of the Minister of Transport and Communications of Ukraine dd. March 21, 2006, No. 254, as a research subdivision at the Department of Structural Mechanics and Hydraulics of the Ukrainian State Academy of Railway Transport (now Ukrainian State University of Railway Transport).The main activities of the Center include:

At present, the service life of numerous structures (carload or truck scales, buildings, bridges, piping) being in operation at the Ukrainian railways is expired. In some cases, such structures are in emergency or pre-emergency condition. The supporting structures should be diagnosed to decide whether their further operation is possible. These issues can be addressed at TCDS.

The personnel of the Centre are highly qualified specialists who have the necessary experience in performing the above works. The professional qualities of the employees of the Centre are confirmed with the qualification certificates of responsible executors of certain types of work (services) related to the creation of architectural objects. The centre is equipped with modern measuring and computer equipment, an accredited laboratory, licensed software complexes for automatic design and calculation.

Since its establishment, the TCDS specialists have been performing assessing the operational properties and restoring the reliability of the bridge and tunnel structures, culverts, reinforced concrete, metal and stone load-bearing structures of industrial buildings and constructions, carload and truck scales, rail and road cranes, and foundations. Over this time, more than 250 projects have been developed to restore the operational reliability of carload scales, more than 50 studies have been carried out with the implementation of new ideas and design solutions at the Ukrainian railways, new technologies have been developed for estimation of load capacity and testing of structures.

For instance, in the cooperation with Kharkivmetroproekt and Kharkivmetrostroy JSC, works have been performed on the experimental determination of the permissible load on the reinforced concrete bored piles laid at the depth of 15.5 m by jacking. The works have been carried out during the construction of the span to Alekseevskaya station of Kharkiv underground.

- Випробування мікропаль у тунелі метрополітену (ст. Ботанічний Сад)

- Установка для випробування буронабивних паль методом вдавлення

Another example of the hardening of weak soils is the use of micropiles. Together with the engineers of Kharkovmetroproekt PJSC, the specialists of the Centre proposed new technology for making micropiles and proved the efficiency of its use. An experimental portable bench for testing piles with the static load was developed to determine the bearing capacity of the piles. These technologies were used for the foundation pinning during the reconstruction of the Kharkiv Regional Philharmonic Hall and the tunnel sections of the Kholodnogorsko-Zavodskaya and Alekseevskaya lines of the Kharkiv underground.

The most indicative projects for assessing the level of work performed by the specialists of the Centre include the development of new high-performance steel-and-concrete and reinforced concrete structures for railway transport facilities and the design of the building of Kharkiv-Balashovsky station, performed as part of the reconstruction of the railway station complex during the preparation of Euro-2012 in Ukraine.

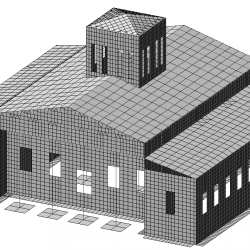

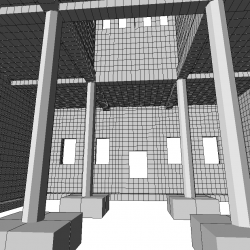

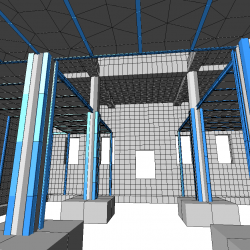

The TCDS employees surveyed the load-bearing structures of the station building and carried out a numerical check of the possibility of destruction of load-bearing structures in case of increasing loads on the central supports, which the provided by the proposed reconstruction project. The degree of stress and deformation distribution was estimated by comparing the results of the initial design of the building and the design after reconstruction with an additional load on the overlap and, as a consequence, the changed characteristics of the base. Numerical analysis of the structure of the station building before and after the reconstruction was carried out using a spatial model in the environment of LIRA software complex.

- Обстеження конструкцій будівлі вокзалу на ст. Харків-Балашовський

The design diagram of the station building before and after the reconstruction

A good example of the cooperation of the Centre with the enterprises of the Southern Railway is the design of reinforced concrete racks. Based on the results of the performed study, the technical conditions for the manufacture according to TU V 26.6-26066189-001 were compiled and adopted: “Reinforced concrete stands for support of 0.4 to 10 kV overhead power lines, outdoor lighting systems and railway signaling systems”.

The data collected by the TCDS specialists at the survey of racks, the findings of their analysis and the results of preliminary calculations enabled to propose new variants of racks that were full-scale tested to study the boundary condition, fracture toughness and load-carrying capacity at the laboratory bench of Kharkiv Reinforced Concrete Structures Plant JV of the Southern Railway.

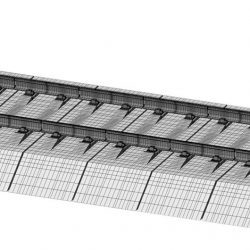

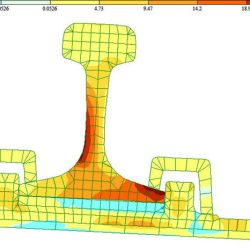

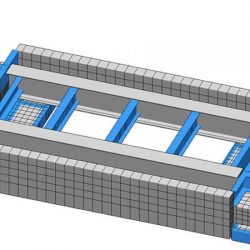

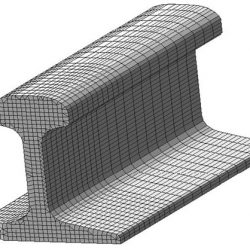

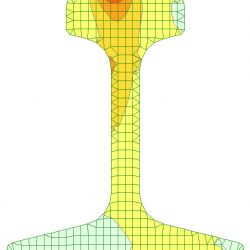

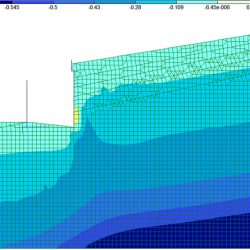

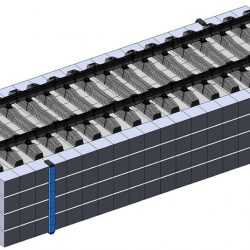

The research of TCDS also includes improving the operational reliability of the upper track structure. For this purpose, a spatial track model is used that takes into account the physical nonlinearity of materials, as well as geometric and constructive nonlinearity, and allows solving a number of contact problems. In particular, this model was used to assess the possibility of using new design solutions for terminals and sub-rail pads.

- Загальний вид розрахункової схеми ділянки колії

- Напруження в рейці та елементах кріплення типу КБ

Within the cooperation with the companies that produce modern strain-gauge scales, the Centre has been carrying out studies aimed at improving the design of such scales, their durability, taking into account difficult operating conditions. Thus, for example, by the order of TOM Technical Research and Production Centre, experimental and theoretical studies of the possibility of using splayed rail joints in the construction of the upper structure of the carload scales were performed, which enabled to improve the smoothness of the movement above the joint, reduce the crushing of the rail head and its horizontal wear, as well as improve the accuracy of weighing.

- Тензометричні ваги виробництва ТНПЦ «ТОМ» під час діагностичного обстеження

- Нова конструкція тензометричних ваг УА ТОВ «КОДА»

Studies and calculations of a splayed rail joint

By the order of the Ukrainian-American enterprise Koda LLC, the specialists of the Center proposed a new design of the railway scales, which significantly improved material consumption. The design provides for a prefabricated structure, which is easy to install on site, thus reducing the cost of transportation and commissioning.

- Вимірювання переміщень в елементах тензометричних ваг SCALEX із зважуванням під час руху

- Під час дослідної експлуатації тензометричних ваг ТОВ «ПУЛЬСАР 92»

The specialists of the Centre have performed significant work to improve performance and weighing accuracy during the survey and trial operation of the strain-gauge scales manufactured by PULSAR 92 LLC for both static and in-motion weighing. An important task for the safe operation of the transport infrastructure is ensuring the stability of the railway slopes, ensuring the strength and strain capacity of the retaining walls, high railways and overpasses for unloading operations.

Modeling the operation of the retaining wall and unloading rack

The Transport Construction Diagnosis Centre of the Ukrainian State University of Railway Transport invites for cooperation everybody who is interested in the diagnosis, inspection, certification and design of transport and other structures.

Contact Information:

Address: room 1.118, Feuerbach square 7, 61050, Kharkiv, Ukraine

tеl/fax (057) 730-10-70

tel. 0508059093 (director Oleksii Lobiak)

e–mail: Lobiak@ukr.net